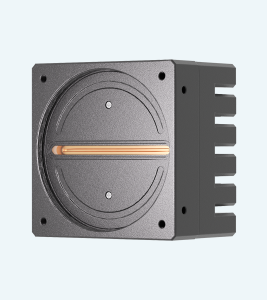

Selecting the perfect industrial microscope camera needs evaluating many factors including resolution, frame rate, sensor type and compatibility with your current microscope system. These factors impact the quality of images captured, speed in processing data and overall system performance. Whether in the field of material science, quality control or biological research- a suitable camera can significantly increase productivity and similarly is simplest for image recording.

First on the list is one resolution that will decide how much detail can be captured by a camera. Cameras with 10-20 megapixel resolution are suitable for imaging applications where fine detail is necessary, such as in metallurgical analysis or biomedical imaging. As an example, a camera that has 16 megapixels is needed for microelectronics inspection to see even the tiniest failures. If a strict focus is high-speed sampling, however, higher frame rate combined with lower resolution might have the preference.

How about then when it comes to frame rate. For real-time monitoring (e.g., inspection and camera) of industrial computers, a 60fps or higher is essential for capturing moving objects in high speeds to avoid any blur. This is typically enough for applications where the sample does not move, e.g. histology or forensic analysis and an inspection of 30fps onPostExecute() […]

Another important thing to consider is the type of sensor. The CMOS sensors are predominant in the case of industrial microscope cameras because they offer faster readout and lower power consumption if compared with CCD sensors. CMOS cameras are perfect for fast data capture and real-time processing applications, such as robotics or live cell imaging. CCDs, by contrast, excel in low-light applications such as fluorescence microscopy.

Dynamic range is another factor you need to take into account — it simply denotes how well the camera can retain detail in both darker and brighter parts of an image. Applications such as metallurgical analysis, in which extremely reflective and dark surfaces may need to be captured within the same image benefit greatly from cameras with a high dynamic range (often 60 dB or more).

The microscope system with which the SDM will be associated must also remain compatible as per need for better integration. To get the best images, the industrial microscope cameras need to be compatible with both optical and mechanical systems of the microscope. A camera with a C-mount interface, for instance,could be easily paired up with many different industrial microscopes. Second, confirm the camera's software also has functions like image stitching, 3D model reconstruction and automated measurement to enable industrial applications.

Latency is another consideration, especially in real-time feedback applications such as machine vision or quality control. One of the other critical aspects in needing low latency cameras is to prevent delay between image capture and its display, imperative when quick decision-making based on seen data needs incorporation. For instance, USB 3.0 cameras provide quick data transfer speeds of up to 5 Gbps so that they are an ideal fit for high-speed imaging tasks with low latencies.

Another consideration — of course, is budget-related. Entry-level industrial microscope cameras with basic features can typically be found for $300-$2,000; while advanced models with high resolution, frame rates and enhanced functionality may run over $2000. The investment should align with the complexity and requirements of the application. Such as, in the case of pharmaceutical track record detection where high resolution images and active evaluation are imperative - having a better camera could present significant possibilities for you to increase speed together with excellence.

David Chen, an optical imaging systems expert explained "Picking an appropriate industrial microscope camera consists of a trade-off among your resolution requirements, speed demands and budget limits that will help you to improve batch processing workflow at reasonable cost".

To sum up, the choice of an industrial microscope camera should be based on consideration of performance requirements and these key parameters: resolution, frame rate image sensor type and system compatibility. To know more about the options available please visit industrial microscope camera.